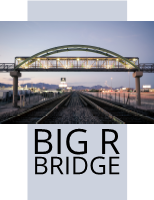

Big R Bridge

The right bridge, built right

When one thinks about bridges, the mind usually pic-

tures the giant, red-orange towers of the Golden Gate

Bridge whose trusses span San Francisco Bay; or may-

be the iconic, castle-like edifices of the Tower Bridge

in London; or perhaps even the spider web-like cables

that hold up New York’s Brooklyn Bridge, connecting

Manhattan with its neighboring borough across the

East River. But, in fact, the world is filled with count-

less smaller bridges, and surprisingly, many of these

lesser structures are not constructed where they sit,

but are actually pre-fabricated by companies who de-

sign and build their components, and then ship them

to their customers for on-site assembly.

Big R Bridge is one such company that designs and

builds these types of pre-fabricated, steel bridge struc-

tures for both the public and private infrastructure

markets. Cameron Klein, the President and CEO of the

45-year old firm, recounts the company’s genesis from

a small farm and ranch store to its current identity as

one of the leading manufacturers in its field: “Big R

Ranch Wholesale Company was the original business.

It was a farm-store chain similar to Tractor Supply or

Murdoch’s, operating in Colorado. They established

Big R Highway Products to make a product called cor-

rugated metal pipe. Years later, several employees

bought that business from the farm and ranch store

and moved it to a different location where they con-

tinued making corrugated metal pipe for drainage ap-

plications. That’s the very beginnings of Big R Bridge.

From those days, they started manufacturing cattle-

guards, steel bridge decking and eventually saw an

opportunity with small-vehicle bridges for the Pacific

Northwest logging industry. It was a kind of happen-

stance beginnings - some entrepreneurs started mak-

ing one product, saw an opportunity in another area,

and said, ‘We think we can make that,’ and they got

into the bridge business. It grew from there over the

years and the company evolved to where it is today.”

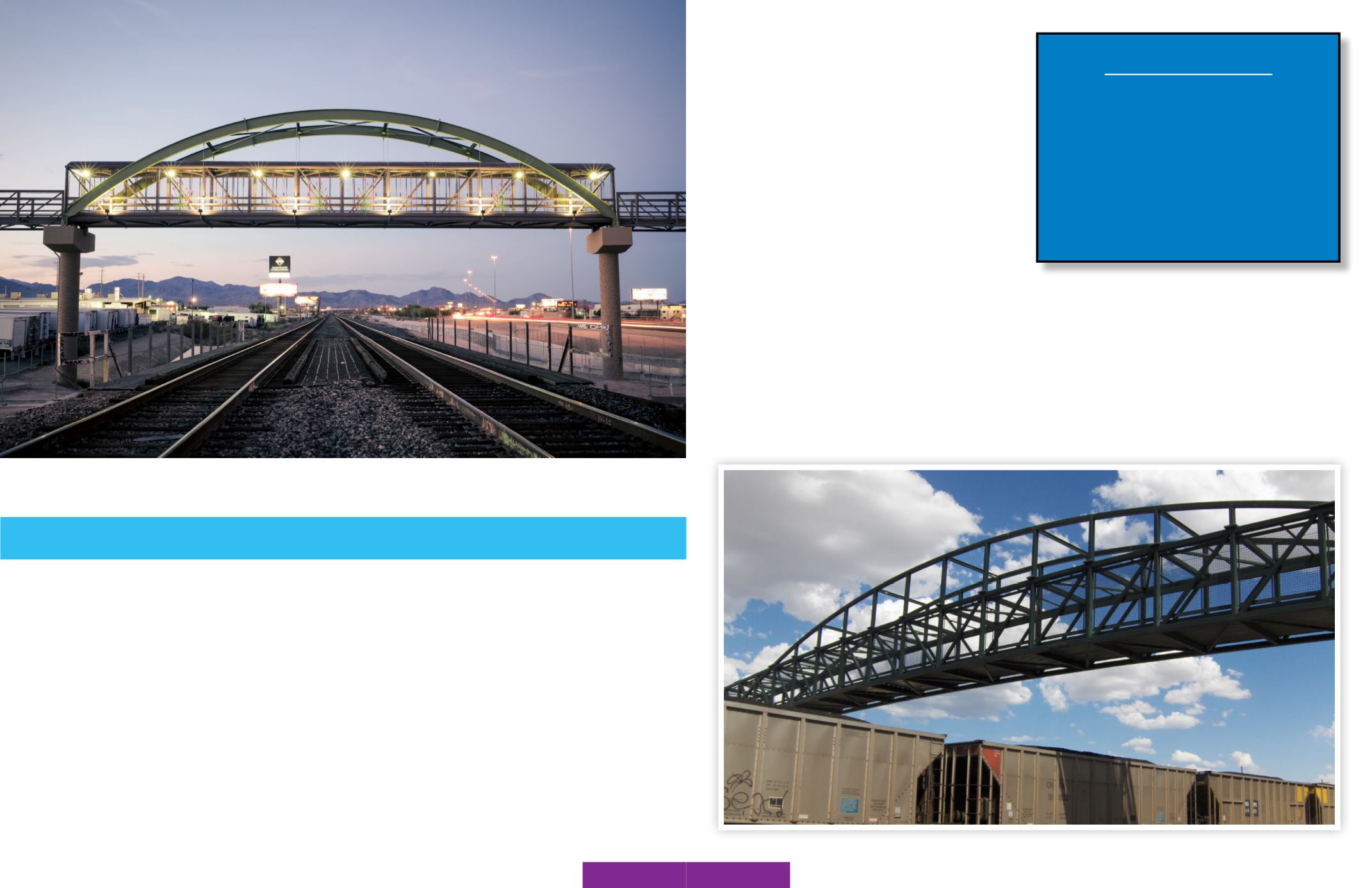

And so today, Big R Bridge, which was acquired by its

parent company, Atlantic Industries Limited of Cana-

da in 2001, has over 130 employees working in three

plants – Greeley, Colorado, Fort Worth, Texas, and

Abingdon, Virginia. Its nation-wide sales team supplies

custom-engineered products in all 50 states, as well

as Canada, Africa, South America, and Asia. Big R has

handled more than 10,000 installations to date and

manufactures over 300 bridges a year. Its customers

range from logging companies, golf courses, and man-

ufacturing plants to the mining and railroad industries,

military bases, and town, county, city, and state gov-

ernments. Its four core products are above-ground

AT A GLANCE

WHO:

Big R Bridge

WHAT:

Manufacturer of prefabricated bridges,

tunnels, and infrastructure components

WHERE:

Headquarters in Greeley, CO

WEBSITE

:

www.bigrbridge.comlogistics

logistics