Business View Magazine

5

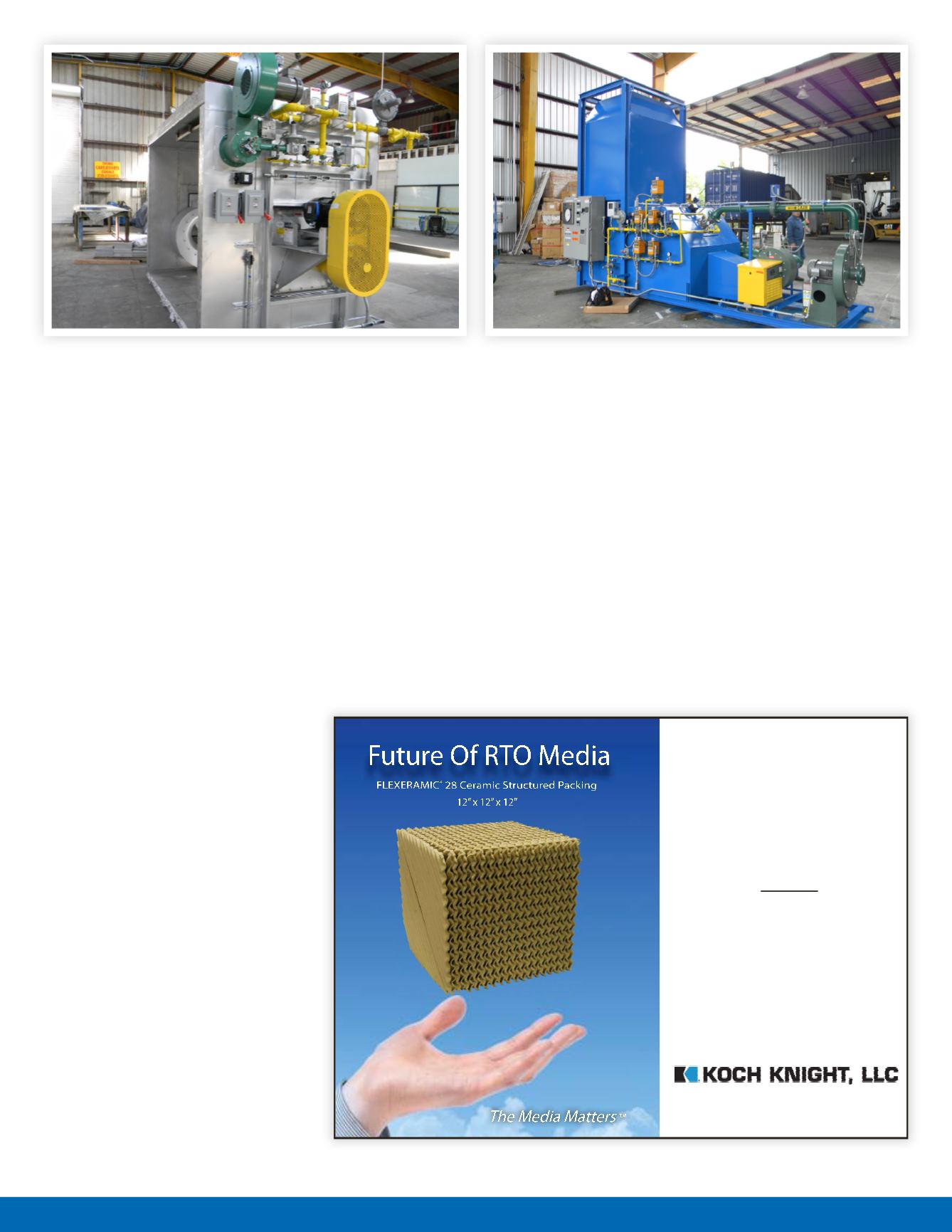

Today, Epcon encompasses a 250,000 square foot,

modern, manufacturing facility on 18 acres in the

Greater Houston area, housing 8 to 10 million dollars’

worth of fabricating machines, CNC (Computer Nu-

merical Control) machines, and other automated ma-

chinery. Products are sold around the world, with sales

fluctuating between 70-80 percent domestic, and 20-

30 percent outside the US.

Product lines include environmental thermal oxidizers,

environmental abatement systems for volatile organic

compounds (VOCs), as well as custom-designed, in-

dustrial ovens and furnaces. Be-

cause of its proven engineering ex-

pertise and on-site manufacturing

facilities, meeting American Pe-

troleum Institute (API) standards,

Epcon is now considered the go-to

source for these high-tech, niche

products. Customers come from

the automotive, aerospace, metal

coatings, internal pipe coating,

flexible packaging, resin manu-

facturing, copper-clad laminates,

industrial finishing systems in-

dustries, and basically anywhere

that curing/heat processing is re-

quired.

Go Green with Epcon

With a mission to “protect the environment through

technology,” Epcon is proud to be advancing in the

area of solar energy production. Its design team has

developed a procedure using existing on-site systems

for the curing and heating processes of solar panel

production - a significant achievement in its ongoing

quest to preserve our natural resources.

Air quality control is another key component of Epcon’s

green focus. Jamaluddin explains, “When the EPA was

born in the early ‘70s, the Nixon administration tar-