Clark Manufacturing builds on success by servicing core customers

The mandate is right there on the website.

“Clark Manufacturing recognizes that satisfied customers and satisfied workers depend on each other. By continually improving the quality of our work and the quality of our workplace, we will maintain our position as a company on the cutting edge.”

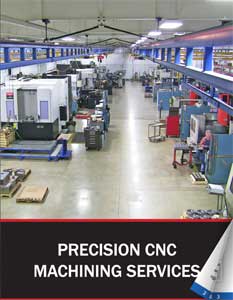

Indeed, Clark Manufacturing Co. has specialized in machining parts for a variety of customers since it began operations in 1975. It has about 100 employees and 35 CNC (computerized numerical control) lathes and machining centers. The purchase of new technology equipment has enabled it to stay ahead of competitors in how it processes and schedules jobs, which also allows it to maintain delivery of quality products – on time and at a competitive price – in an atmosphere of continuous improvement.

“(Founder Gary Clark) saw a need – in order to service some of the local manufacturers here in this region – to purchase a CNC lathe and start to get his name known about supplying a CNC turning service locally in the area,” said Cameron Fuller, now co-owner of the business.

Clark retired and sold the business to Fuller and three other employees 10 years ago, but two of the partners have also since exited – leaving the reins to Fuller and one remaining member of the group.

Prolonged growth across several industries prompted a need for additional

manufacturing space, which resulted in Clark’s move into a clean, modern 55,000 square-foot facility in October 2008. These days, it continues to maintain its headquarters in Traverse City, Mich., near Grand Traverse Bay.

The company had originally been equipped with 35,000 square feet of manufacturing space, and went through a few years where it leased an additional 5,000 square feet, too.

“Having a new building with more space available, we’ve been able to expand,” Fuller said.

“Having a new building with more space available, we’ve been able to expand,” Fuller said.

Clark added multi-tasking turning and milling equipment, including four Mazak 730-5X VariAxis machines. Faced with numerous orders for large hydraulic manifold blocks, the company opted for the VariAxis over conventional vertical or horizontal machining centers.

Advantages in quality and productivity have also been realized with the addition of eight Mazak live-tooling lathes, along with three Mazak HCN horizontal machining centers.

“We have the capabilities to machine just about anything,” Fuller said. “We can handle everything from one-piece prototype orders to blanket orders which we will ship from our inventory.”

Ninety percent of Clark’s business is done with its top-five customers, four of which are in energy-related sectors that include natural gas compression and hydraulic systems on drill rigs, while another supplies medical clamping instruments for surgical applications.

“We made the strategic decision that our business growth is coming mainly with those top-tier customers,” he said. “As they grow and they ask us, ‘We’ve got these other parts that we’d like to have you do’ or ‘We’ve got more of these parts,’ then we’ll expand, get another machine tool and hire people accordingly to be able to grow with those customers. We’re not actively seeking new business right now. Business comes to us by growth in those particular customers or by word of mouth.”

Fuller said quality, competitive price and delivery are characteristics most sought by that customer base, and providing them consistently has enabled Clark to develop a strong flow of repeat business.

“That’s the nature of the business,” he said.

“We don’t have high-production automotive volume-type jobs. Our jobs range between four pieces and 20 pieces, but we may be doing that particular part for that customer four, five or six times over the year. We also have inventory stocking programs set up with those particular customers, where they give us an annual forecast of how many parts that they’re going to use for the year.

“They’ll give us a blanket order and we’ll go ahead and schedule that job into our system, so, when they need more parts, we’ll have the parts already finished on the shelf that meet their requirements, and that kicks out another job order in our shop.”

Providing great service to customers  requires attention to serving employees, too.

requires attention to serving employees, too.

Fuller said customer satisfaction is impacted and determined by the degree of employee satisfaction within an operation, which has created a mandate at Clark to ensure not only the training, tools and operational space to conduct work, but the requisite benefits and incentives, too.

Among them are job promotions and profit-sharing opportunities.

“Very few job shops have the capability to provide that kind of benefit,” he said. “But it’s important to the team, and this is a company which depends on a lot of teamwork.”

Going forward, the recipe for success isn’t likely to change.

Fuller said the business model would continue to be constructed with the most significant customers in mind, and that Clark’s growth will remain in conjunction with their growth. Also part of the plan will be continued support of local career tech centers that play a role in developing the future workforce.

“We have to remain competitive and invest back into our business for those customers to remain with us,” he said. “That’s what’s been the success of our business for the last 40 years, so we expect to follow that same path for the future.”

AT A GLANCE

WHO: Clark Manufacturing Co.

WHAT: Machine shop with more than 30 CNC (computerized numerical control) turning and milling centers, three horizontal, and four VariAxis milling centers, and eight lathes with live tooling for milling capabilities

WHERE: Corporate headquarters in Traverse City, Mich.

WEBSITE: www.ClarkMfg.com